Our Projects

Transformer Relocation

The first stage of the project was the transformer pre-testing, dismantling, and preparation for transport which included removal of the radiator, conservator, gas piping, bushings, and insulating oil. The transformer tank and tap changer cabinet were continuously purged and then pressurized with dry air for shipment. When landed at the new location, a thorough internal inspection of the windings and on-load tap changer were performed. The re-assembly included installation of the re-gasketed radiators, replacement of the primary and secondary bushings, and reinstallation of the conservator, piping, and mechanical seals. The transformer was then vacuum

filled with new insulating oil. The final stage of the project was recommissioning the transformer which included insulation resistance, power factor insulation testing of the main windings and bushings, winding resistance on all tap positions, sweep frequency response analysis, and

verification testing of all instruments and accessories.

Haul Truck Trolley Assist

QED provided the onsite project commissioning management to create daily plans and coordinate events for a safe and successful project from the utility interconnection substation through to the trolley line connected haul trucks. QED also provided operations readiness and execution management, working with all departments within the mine to ensure readiness during project handover to operations. The project included construction of a 138 kV substation with a total connected load of 20.5 MW, a 25 kV overhead distribution line, a DC E-House that converts 25 kV AC into 1800 V DC, a 1 km haul truck trolley line, and 7 haul trucks which were upgraded with pantographs and new control systems. Upon completion, the new haul trucks run on DC-electric power up a 10% grade, during which time diesel consumption is negligible reducing overall operating costs and greenhouse-gas emissions

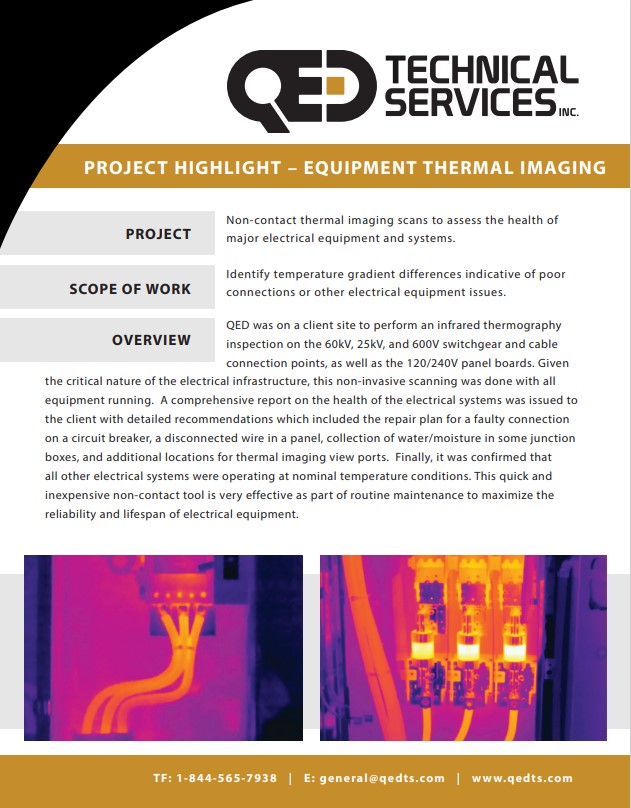

Equipment Thermal Imaging

QED was on a client site to perform an infrared thermography inspection on the 60kV, 25kV, and 600V switchgear and cable connection points, as well as the 120/240V panel boards. Given the critical nature of the electrical infrastructure, this non-invasive scanning was done with all equipment running. A comprehensive report on the health of the electrical systems was issued to the client with detailed recommendations which included the repair plan for a faulty connection on a circuit breaker, a disconnected wire in a panel, collection of water/moisture in some junction boxes, and additional locations for thermal imaging view ports. Finally, it was confirmed that all other electrical systems were operating at nominal temperature conditions. This quick and inexpensive non-contact tool is very effective as part of routine maintenance to maximize the reliability and lifespan of electrical equipment.

Transformer Repair

The first stage of testing determined that the insulation resistance of the secondary winding was low although power factor and dissipation tests of the primary windings and primary bushings were within acceptable ranges. At this time inspections of the insulating oil and other components of the transformer were conducted. With the initial stage of the process yielding potentially positive results, the second stage of the inspection was justified. Sweep frequency response analysis testing was completed before removing the transformer insulating oil to

temporary storage. A thorough internal inspection on the windings and detailed measurements of the defective parts allowed for fabrication and procurement of custom LV bushings and mounting plates. A final site visit resulted in the installation of all new parts including custom welding of bushing mounting plates, installation of custom bushings, modification and re-design of transformer throat, re-design and re-wiring of protection circuits, leak repair, oil processing, and final testing and energization

Wind Farm Commissioning

Energy Audit

In May 2019, QED completed a BC Hydro funded level III plant wide audit at a BC mining operation. The project included a multi-day site visit to observe operations, interview staff, collect data and create a potential energy improvement project list from both the mine and milling operations. While off-site, detailed evaluations were completed on each potential project with the most viable being recommended for further study. If all potential projects were executed, they would result in a 15% reduction in electricity and a 5% reduction in diesel each year. If all projects were implemented, the resulting savings would be $8.7 million per year.

Energy Billing

In 2020, QED assisted a BC mine in setting their Customer Baseline Load (CBL), which is the basis for electricity billing with BC Hydro transmission rate customers. This one-time exercise uses the previous 12 months of energy consumption as a typical year. Any unusual events from the basis year were quantified for BC Hydro review and acceptance. The energy impacts of these events were added to the CBL. To ensure the mine site ended up with a right sized CBL, detailed analyses were performed to ensure the CBL would be representative for current and future operations loads. The business case was presented to management, which included opting out of the freshet rate reduction program for one year to include all energy in the CBL setting process. $3.26 million savings were realized in 2021, which is an 8.8% annual cost reduction when comparing their new Stepped Rate to the previous Blended Rate.